Load Cells in Crane & Hoist Weighing Systems

How to Choose the Right Load Cell for Your Crane

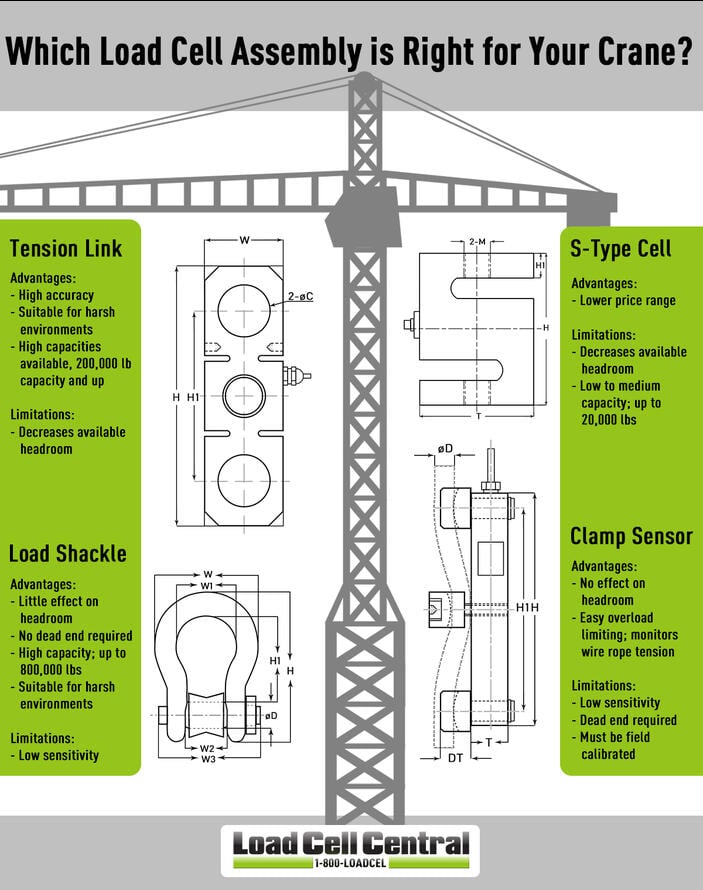

Tension load cells are categorized by the way the strain gauge sensor deflects when experiencing strain. A tension load cell is pulled and stretched, rather than compressed. They are used to measure tensile or “pulling” loads, making them ideal in crane and hoist weight monitoring. Clamp sensors, tension links, s-type load cells, and load shackles are most commonly used in this application.

Clamp sensors, like the DLWS, attach directly to the dead-end of crane wire ropes. This enables them to measure the load without impacting the amount of headroom a crane operator has to work with. This type of load cell is ideal when overload limiting is needed. Using a digital indicator or load cell amplifier, the system can provide relay output to activate a light, shut down the lifting operation, activate an audible alarm, or any combination of these. Read More

Tension link load cells, like the CTL2 or DCL10, are typically installed above the hook of the crane. As the name suggests, these cells are used as a link between a shackle and the object to be measured. They are the most common type of load cell used in lifting and weighing applications, particularly in harsh environments. These applications are more accurate than clamp-on or load shackles load cells. They are also simple and easy to install, but do result in a loss of headroom due to the addition of the load cell assembly. This is typically between 12" to a few feet. The load can either be displayed on the link itself or on a separate indicator. These systems are also available with wireless capability to improve versatility and logistics. Tension links are used for heavy loads, typically between 10,000 and 200,000 lbs although larger capacities are available.

S-type load cells, like the XTS4 or XLS2, can also be used similarly to a tension link. As the name implies, these load cells are shaped like the letter S. The strain gauge sensor is located in the center beam of the load cell. S-type cells are used more commonly for small to medium loads and come in capacities up to 20,000 lbs.

Load shackles are an excellent solution for applications where a dead end is not available and where headroom is of the utmost importance. A shackle is a U-shaped piece of metal with a clevis or bolt across the opening. With load shackles, a load pin is incorporated into the shackle design so the load can be monitored. Load shackles are used in medium to heavy weighing applications. Standard capacities start around 2,000 and can exceed 800,000 lbs. They are available in both wired and non-wired (wireless) versions.

Often, the simplest solution for this type of application is to use an all-in-one crane scale, which has the advantage that the load cell, hook, and display are combined into a single unit. Versatility, however, is limited. When using the other load cells described previously there is freedom in choosing different types of displays and software as well as increased versatility in harsh environments and underwater applications.