Basic Working Principle of a Strain Gauge Load Cell

September 20, 2019

A load cell is a type of transducer, which is a device that converts energy from one form to another. Load cells are a type of force transducer, converting force exerted on the load cell a measurable electrical signal. The strength of the signal changes in proportion to the force applied.

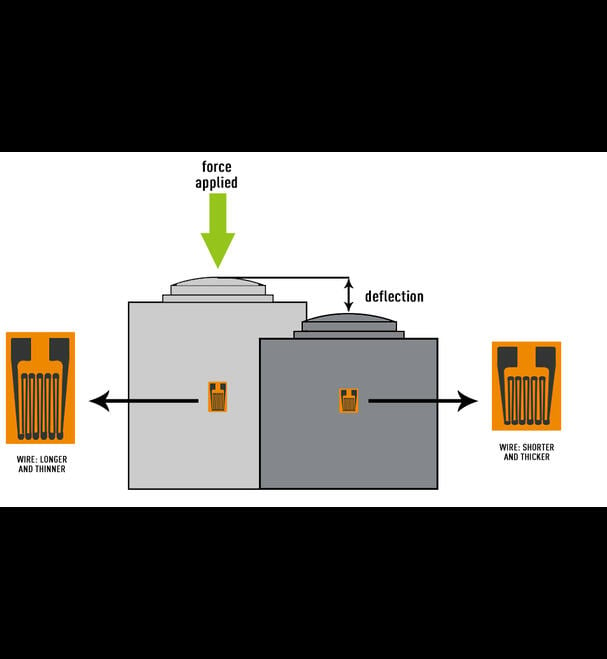

The most commonly used type of load cell in industrial applications is the strain gauge load cell. A strain gauge load cell is comprised of a solid metal body (or “spring element”) on which strain gauges have been secured. When a load is applied, the body of the load cell deforms slightly and experiences deflection. Deflection refers to the change of length of the load cell along the primary axis when a load is applied. In a compression load cell, the deflection causes the gauge to become shorter and thicker. In a tension load cell, the gauge is stretched and becomes longer and thinner.

In response to the body shape changes, the strain gauges also change shape. This, in turn, causes a change in the electrical resistance of the strain gauge which can then be measured as a voltage change. Since this change in output is proportional to the amount of weight applied, the weight of the object can then be determined from the change in voltage.

For more information, please see our white paper on Load Cell and Strain Gauge Basics