Load Cell Accuracy

October 29, 2019

Accuracy Considerations When Choosing a Load Cell

Among the many things to consider when choosing a load cell is how to choose the most accurate load cell given your application. Load cell accuracy is indicated in the specifications section of the datasheet. Some of the items listed are combined error, hysteresis, non-linearity, repeatability (non-repeatability), creep, and temperature effects. The vast majority of load cell data sheets will express accuracy-related specifications in terms of % full-scale output (FSO); also called rated output (RO) (for more information on these terms, see our white paper on Understanding Load Cell Specifications).

Specifications to Consider

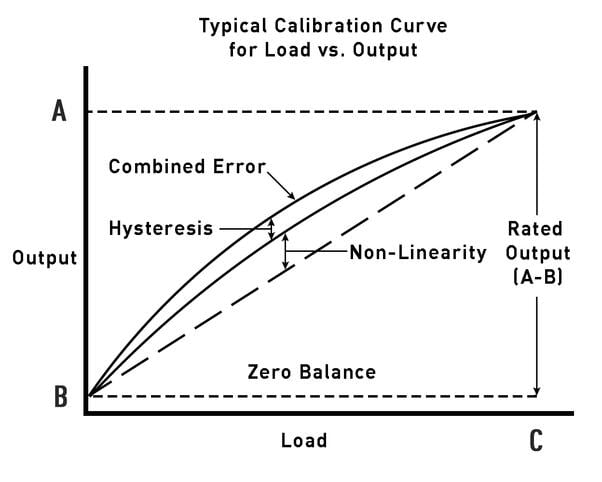

When it comes to overall accuracy under ideal conditions, the most important specifications to look at are non-linearity, hysteresis, and combined error. Non-linearity establishes the margin of error for the load cell over its operating range from zero load to maximum capacity. This difference is shown on a graph as a curve deviating from the straight line of theoretical ideal (see load cell calibration curve below). Hysteresis is the difference between output readings for the same load; one being taken as the load is increased from zero, and the other as it is decreased from the load cell’s rated capacity. Combined error, as its name implies, is the combination of non-linearity and hysteresis.

Application Considerations

In addition to accuracy regarding baseline, there are three important application-dependent specifications to consider. These specifications are repeatability, creep, and temperature effects.

Repeatability (or non-repeatability) refers to the ability of a load cell to maintain consistent output when an identical load is repeatedly applied. Example: If a load cell’s rated output is 3.00 mV/V and repeatability is listed as 0.01% then the output of a 1,000 lb load cell could vary up to 0.0003 mv/V (0.1 lbs) for repeated loads of equal weight.

Repeatability is especially important for applications such as checkweighing where the goal of the process is to make sure that numerous repeated loads are as identical as possible.

Creep error occurs when a load is applied to a load cell over an extended period of time. Over time, the output value will gradually change in proportion to the amount of time that has elapsed. Creep is expressed in % FSO over 30 minutes. Example: If a cell’s rated output is 3.00 mV/V and the creep error is 0.02% then the output of a 1,000 lb load could change by .0006 mV/V (0.2 lbs) over 30 minutes.

In an application requiring a load to be left on the scale for an extended period of time, a load cell with a very low creep error would be most desirable. Conversely, in an application where loads are removed shortly after the weight is obtained creep error is a non-issue.

Temperature fluctuation or excess can also impact the accuracy of a load cell. These effects on output are listed as “temperature effect on zero”, where temperature causes the entire output range to shift, and “temperature effect on output”, referring to the change in the load cell’s sensitivity. The temperature effect is usually measured in % FSO per 10°C.

Compensated temperature range is also listed in the specifications. This is the range of temperature within which the load cell accuracy will be maintained. The above temperature effects listed need to be considered when operating outside of this range. Example: Using a 1,000 lb load cell with the following specifications: rated output 3.00 mV/V, compensated temperature range 10°C - 40°C, temperature effect on zero 0.05% FSO, and temperature effect on output 0.03% FSO. Using this load cell in an environment of 50°C would cause a zero shift of up to 0.0015 mV/V (0.5 lbs) and a sensitivity change of up to 0.0009 mV/V (0.3 lb).

Consideration of temperature error is important when working in an environment with large temperature fluctuations, such as outdoors or in excessively hot or cold indoor environments. In controlled or naturally stable environments where the temperature stays within the compensated temperature range, temperature effects are negligible.

Other Factors

Load cell accuracy can also be greatly influenced by factors arising during installation. Please see our blog on Load Cell Installation Tips for more information.

What are some important conditions to consider that may affect the accuracy of my load cell?

Environmental factors can greatly affect the way load cells function. Here is a summary of the major items to consider:

- Temperature - On a load cell’s specification sheet, you will see listed both operating temperature range and compensated temperature range. The compensated temperature range is the range of temperatures at which the load cell can perform within normal specifications. The operating temperature range is the range at which a load cell can perform without permanent damage occurring to the load cell or its performance. Using a load cell outside of these parameters will result in both inaccurate measurements and permanent damage.

- Surface - The weighing platform must be level and free from dirt and debris.

- Dust - If using a load cell in a dusty environment, it must be protected from dust ingress. Should have an ingress protection rating of IP60 or higher.

- Moisture - Load cells are able to perform in virtually any level of moisture from fog and humidity to complete submersion. In order to do so, they must be sealed appropriately according to the Ingress Protection (IP) rating system.

- Damage - Visible indicators of damage include rust, corrosion, cracks in welds or other materials, dents, and other deformation of the body of the cell. Load cells with any visible signs of damage should be tested.

How do I determine the appropriate IP rating for the load cell in my application?

The IP rating chart is used to express the degree of ingress protection an electrical enclosure has against solid objects, dust, accidental contact, and water. The rating consists of the letters IP followed by two digits. The first digit corresponds to the level of protection from the ingress of solid foreign objects. Ratings range from 0 (no protection) to 6 (dust-tight). The second digit corresponds to the level of protection against the ingress of water. These ratings range from 0 (no protection) to 8 (immersion beyond 1 m).