Single Point Load Cells: What They Are And How They Work

June 12, 2024

Single point load cells are integral components in the realm of weight measurement technology, renowned for their precision and efficiency. These specialized devices play a crucial role in various industries, from manufacturing and logistics to retail and healthcare.

Understanding Single Point Load Cells

Definition and Functionality

Moment compensation is a critical feature in single-point load cells. The term "moment" refers to the external force applied off-center, which could potentially lead to measurement errors in less sophisticated load cells.

Types of Single Point Load Cells

Single point load cells come in various designs and capacities, tailored for different industrial needs.

- Aluminum Load Cells: Cost-effective, suitable for general use.

- Stainless Steel Load Cells: Corrosion-resistant, ideal for harsh environments.

- Alloy Steel Load Cells: Durable, and versatile for various weighing systems.

Benefits of Using Single Point Load Cells

- High accuracy, reliable measurements.

- Moment compensation capability.

- Facilitates high-speed operations.

- Quickly provides precise readings.

- Increases processing productivity.

- Versatile in various applications.

Working Mechanism of Single Point Load Cells

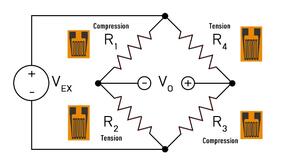

The working mechanism of a single-point load cell involves its ability to detect the force applied to its surface and convert this mechanical force into an electrical signal. The core component of the load cell, the sensing element, typically uses strain gauges that are bonded to a flexible beam. The strain gauges measure the deformation of the beam when a load is applied, and this deformation is converted into an electrical signal proportional to the load.

Load Cell Sensing Element

The sensing element in a single-point load cell is crucial for its function. It typically involves one or more strain gauges that are precisely attached to a deformable structure within the load cell. When force is applied, the strain gauges experience deformation, changing their electrical resistance. This change in resistance is measured and processed to provide an accurate output of the load weight.

Principle of Operation

The principle of operation for single-point load cells is based on the electrical resistance change in the strain gauges due to mechanical deformation. As load is applied, the strain gauges are stretched or compressed, altering the voltage output from the electrical circuit within the load cell. This output is then calibrated to reflect the actual weight of the applied load accurately.

Factors Affecting Performance

Several factors can affect the performance of single-point load cells, including environmental conditions such as temperature and humidity, electrical interference, mechanical alignment, and the physical condition of the load cell itself. Proper installation, routine calibration, and maintenance are necessary to ensure that the load cells perform optimally over their service life.

Applications of Single Point Load Cells

Single point load cells are highly versatile, serving a range of industrial applications due to their robust design and precise measurement capabilities.

- Industrial Weighing Scales: Ideal for platform scales, these load cells provide high accuracy in commercial weighing applications.

- Batching and Filling Systems: They ensure precise measurements, crucial for maintaining consistency in material handling and packaging.

- Checkweighing: Employed in quality control processes to ensure product weight meets specified standards.

- Materials Testing: Crucial for determining the mechanical strength of materials and components.

Installation and Calibration of Single Point Load Cells

Single-point load cells are designed for easy installation and do not typically require a complex mounting assembly. This simplicity is due to their inherent moment compensation which allows for accurate readings even when the load is not perfectly centered.

Proper Mounting Techniques

Single point load cells benefit from precise installation for longevity. Correct mounting minimizes mechanical stress, ensuring accurate measurements.

Calibration Procedures

Regular calibration maintains accuracy. Comparing outputs with standard weights and adjustments ensures consistent performance.

Troubleshooting Common Issues

Routine checks and calibration adjustments resolve signal fluctuations or inaccuracies, sustaining reliable load cell performance.

Future Trends in Single Point Load Cell Technology

Wireless Connectivity

Upcoming models are expected to feature integrated wireless systems for easier data transmission and system integration.

Integration with IoT Devices

This will allow for real-time data analysis and system monitoring from remote locations, enhancing operational efficiency.

Advancements in Material Science

Innovations in materials are anticipated to further enhance the durability and performance of load cells in extreme conditions.

For more detailed information on our single point load cells and to explore how Load Cell Central can help optimize your application, please visit our website.