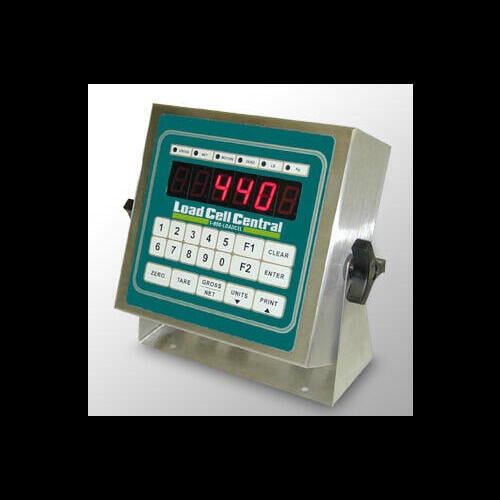

440 440 Scale Display

Features

- 1" tall 6-digit LED display

- Stainless steel enclosure suitable for use in washdown areas

- Full numeric keypad for easy data entry

- Selectable 5-point calibration for improved accuracy

- 20-bit A/D with 60 samples/second conversion rate

- Direct to PC/PLCoutput via RS232, RS485, or USB by using an adaptor

- Powers up to 12 x 350 Ω or 24 x 700 Ω load cells

- Digital port for relay control and remote operation

- 32K RAM provides 500 ID storage (part, truck, etc.)

- Easy setup

- Toll-Free Technical Support

Reviews

There are no reviews yet for this product. Write a Review

Write a Review

Load Cell Central's 440 scale controller is nearly identical to our model 430 except that the enclosure is large enough to fit the 8-channel relay board internally. It's a versatile indicator for use in various industries and applications that can range from basic weighing and material testing to more complex formula batch weighing systems. The LCC 440 is housed in a rugged stainless steel enclosure and provides a universal mounting bracket for wall or desk mounting. The viewing angle can be adjusted for the best possible view of the weight. The bright red one-inch-high LED display makes it easy to read the weight from longer distances compared to other indicators. The keyboard is equipped with spacious keys that provide tactile and audible feedback to confirm data input.

The LCC 440 is configurable using a straightforward and adaptable macro language known as Scale Basic™. Apart from the pre-existing operational modes, Scale Basic empowers you to tailor the functionality of the LCC 440 to suit your specific application needs. The Scale Basic language encompasses a diverse range of commands and functions, covering mathematical operations, setpoints, timers, ID storage, I/O control, message display, data entry, and program sequence control, among various others. Programming the LCC 440 can be performed through the keyboard or a PC using the optional EZ-LINK™ software that eases setup and programming.

Brochures

Pre-Programmed Modes

-

MODE 0 - Standard

Fundamental gross, net weighing functions and tare. -

MODE 1 – Setpoint Fill

Fill to a designated setpoint with relay output control and printing of the weight. -

MODE 2 - Checkweigh (Over/Under)

Furnishes 3 TTL outputs along with 2 setpoints, signaling weight conditions as "Over," "Under," and "Between." These outputs can be utilized to activate lights or alarms. -

MODE 3 – Weighing-In/Out of Vehicles with Cumulative Summaries

A Weigh-In/Out program designed for handling up to 500 vehicles, retaining cumulative totals for each vehicle, and offering reporting capabilities. -

MODE 4 - Automatic Weighing for Multiple Containers/Axles

Automatically weighs and prints each load placed on the scale, assigning sequential numbers to each weight and accumulating them; the overall total can be printed by manual or automatic means; incorporates traffic light control features. -

MODE 5 - Automatic Axle Weighing (Extended Scales)

Similar to Mode 4, but with automatic taring of previous axles. -

MODE 6 – Identification (ID) Tare, Printing, and Totals

Allows for tare entry and retrieval by ID; prints ID, sequence number, and GTN weights; maintains cumulative totals by ID; includes reporting functions. -

MODE 7 - Peak Hold Operation

Displays or prints the highest detected gross or net weight.

Options

- Panel Mount

Panel mount enclosure model 440PM - Parts Counting

Parts counting and weighing program - Quick-Disconnect Kit

Amphenol-type connector on the back of the indicator includes a mating connector - 12-28VDC Operational

Low voltage power supply - Module for Analog Output

Complete isolation with a range of 0-10VDC or 4-20mA; 16-bit resolution - External Relay Box

4-channel external relay box model 8501 - Relay Board

Internal 8-channel relay board - Relay Modules

Input/output solid-state (AC/DC) relays - Clock Module

Time and Date Clock - High-speed (HS)

100 samples/second conversion rate; high-speed process control applications - EZ-LINK™

PC software; facilitates configuration and Scale Basic™ programming - IS Barriers

Hazardous location intrinsic safety barriers - Z-Purge Ready (NFPA Type Z)

Z-Purge ready enclosure for use with purging system in Hazardous locations

There are no reviews yet for this product. Write a Review