Load Cell Types and Uses

With the myriad of design styles available, it is often extremely difficult to determine what type of load cell will work best for you. To help you get started, we have put together a general guide to load cell types and how each is typically used. Please remember that it is always best to check with one of our experts to ultimately determine the perfect load cell for your application.

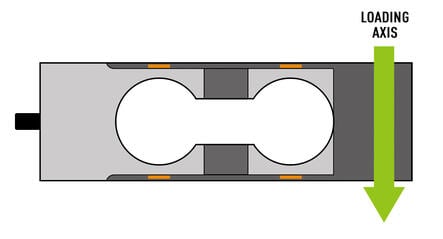

Single point (binocular)

The most common type of load cell sold, single point load cells are low capacity compression load cells. Accurate and reliable, they also have the capability of measuring off-center loads making them the ideal choice for smaller scales, batching scales, counting scales, checkweighing systems and much more.

Shape

Horizontal rectangular “beam” shaped spring element with parallelogram structure (inside being fully machined out).

Loading Axis

Perpendicular to the horizontal axis, force applied to the end of the beam opposite the fixed (mounted) end.

Strain Gauge Placement

Top and bottom of beam on the outer surface of the parallelogram shape, parallel to one another to measure bending strain.

Beam load cells — 3 major types

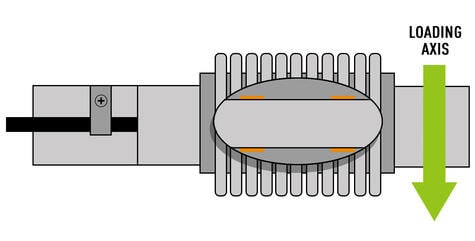

Bending (bellows) beam

Economical and versatile, bending beam load cells are ideally suited to low capacity vessel weighing, checkweighing, and process weighing.

Shape

Horizontal rectangular “beam” shaped spring element.

Loading Axis

Perpendicular to the horizontal axis, force applied to the end of the beam opposite the fixed (mounted) end.

Strain Gauge Placement

Top and bottom of beam, perpendicular to one another to measure bending strain (usually covered by bellows to protect the gauges).

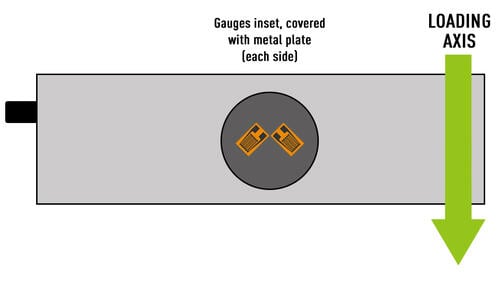

Shear beam

Shear beam cells are compression load cells best suited for low to mid-range capacity weighing, particularly vessel and tank weighing and low profile process applications.

Shape

Horizontal rectangular “beam” shaped spring element.

Loading Axis

Perpendicular to the horizontal axis, force applied to the end of the beam opposite the fixed (mounted) end.

Strain Gauge Placement

Bonded at 45º angles on either side of the beam to measure shear strain across one cross-section of the spring element.

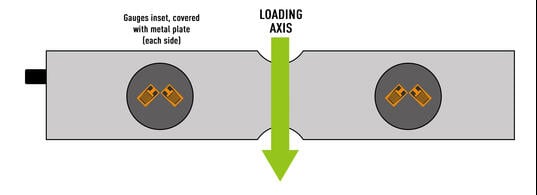

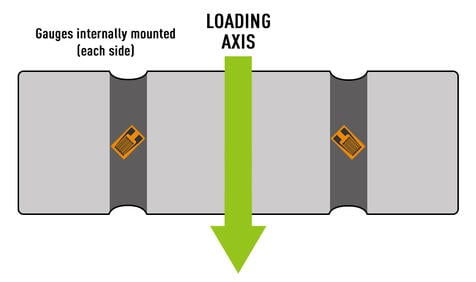

Shear beam (double-ended)

In contrast to the single-ended shear beam cell, which is secured at one end with a load applied to the other, a double-ended shear beam is secured at both ends with the load applied in the center. These cells are often used in tank and hopper weighing and truck scales and are available in higher capacities than single-ended varieties.

Shape

Horizontal rectangular “beam” shaped spring element.

Loading Axis

Perpendicular to the horizontal axis, force applied to the center of the beam with both ends fixed (mounted).

Strain Gauge Placement

Bonded at 45º angles on either side of the beam to measure shear strain across two cross-sections of the cell.

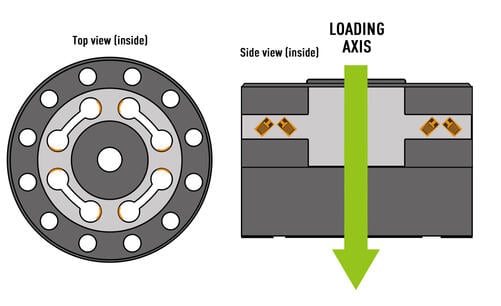

Pancake (shear web type)

Pancake load cells offer a very low-profile design for medium to high capacity load cells. They can be mounted between two components for compression, or used in tension via threaded holes. Shear web pancake load cells are able to provide accurate results even in the instance of off-axis loading.

Shape

Low profile cylinder-shaped hub with multiple beam “arms” connecting to the outer body.

Loading Axis

Perpendicular to the horizontal axis, force applied to the geometric center of the cell where the beam arms connect.

Strain Gauge Placement

Bonded at 45º angles on arms of the spring element to measure shear strain.

Load pin

Load pins replace a pin or axle on which force is applied. The design and structure of these cells is highly customizable and can be used at very high capacities.

Shape

Rod-shaped spring element.

Loading Axis

The central section of the spring element, force applied perpendicular to the horizontal axis.

Strain Gauge Placement

Bonded at 45º angles on specified areas on the spring element to measure shear strain.

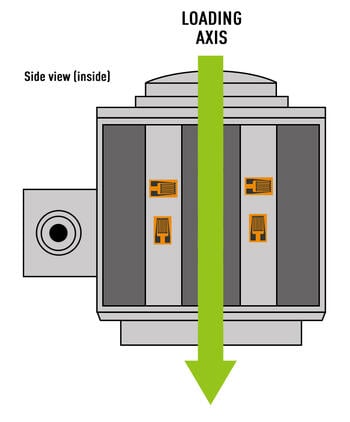

Canister (column)

The canister load cell is the earliest load cell design. Available in tension or compression, column load cells are especially suited for high capacity applications. The heavy-duty nature of the design, unless improperly loaded, is resistant to bending and deforming. Canister load cells are commonly used in truck and railroad scales.

Shape

Cylinder shaped spring element.

Loading Axis

Geometric center, perpendicular to the horizontal axis.

Strain Gauge Placement

Applied to column or columns on the interior of the load cell, placed at 90º angles to measure axial and transverse strain.

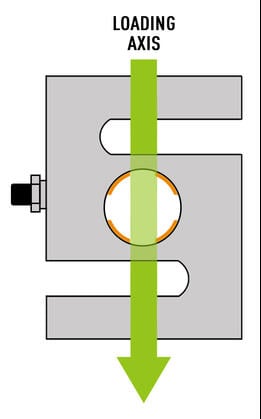

S-Type

The aptly named s-shape load cell is a low to mid-capacity tension load cell that works in both tension and compression. More commonly used in tension applications, the s-cell is typically found in hanging scales or suspended weighing applications. Fitted with eye bolts at the top and bottom, the cell can be suspended from shackles or mounted between two items.

Shape

S-shaped spring element.

Loading Axis

Geometric center, force applied perpendicular to the horizontal axis.

Strain Gauge Placement

Applied to the inside of a machined out circle on the interior of the load cell, placed parallel to one another to measure bending strain.

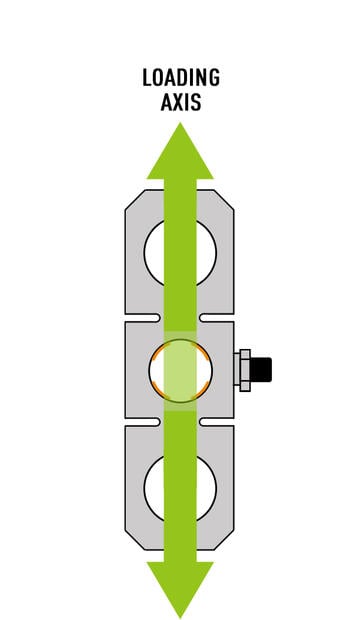

Tension link

Tension link load cells are extremely versatile with customizable capacity making them able to be used in low, mid, and high load application. Tension links are used in tension applications such as crane and hoist scales, pull testing, and tensile strength measuri

ng systems.

Shape

Typically “figure 8” shape, designed as a “link” between cable/rope/chain (often on a crane or hoist) and load being weighed.

Loading Axis

Along the vertical axis, geometric center.

Strain Gauge Placement

Applied to the inside of a machined out circle on the interior of the load cell, placed parallel to one another to measure bending strain.

When is it necessary to use a multiple load cell system vs. a single cell system?

The number of load cells needed depends on the physical size of the load, and the method being used to obtain the measurement.

For example, let’s compare two, 2 tonne loads that must be measured very differently. If weighing 2 tonne shipping containers, one option would be to use a crane or hoist with one load cell employed. The load cell would be a 2.5 t capacity (minimum) tension link load cell.

In contrast, weighing a 2 tonne truckload of gravel would be best done on a platform scale using 4, 1 tonne load cells.